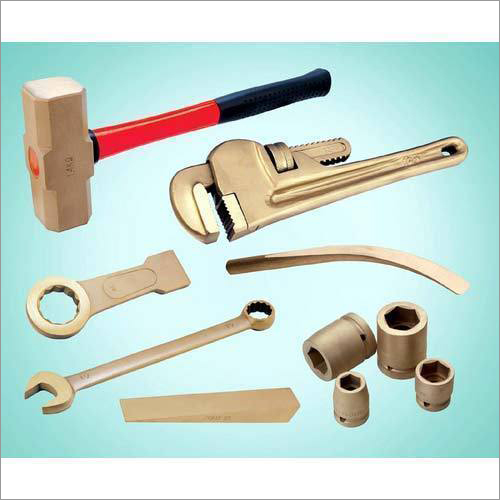

Non Sparking Tools Gedore

4000 INR/Set

Product Details:

- Product Type Non Sparking Tools Gedore

- Color Golden

- Usage Industrial

- Type Hand Tool Parts

- Material COPPER TAITANUM

- Click to View more

X

Non Sparking Tools Gedore Price And Quantity

- 1 Set

- 4000 INR/Set

Non Sparking Tools Gedore Product Specifications

- Non Sparking Tools Gedore

- Golden

- Industrial

- COPPER TAITANUM

- Hand Tool Parts

Non Sparking Tools Gedore Trade Information

- Cash on Delivery (COD) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cash in Advance (CID) Cheque Cash Advance (CA)

- 100 Set Per Day

- 1 Week

- BOX PACKING

- Dadra and Nagar Haveli Gujarat Daman and Diu

Product Description

Non Sparking Tools Gedore

Accidents on drilling platforms, in chemical plants, in coal mines and in the production of oil/gas and transportation of explosive substances, such as on tankers, are often caused by sparks. That is why the recommendation is to use gedore non-sparking tools in all working areas where combustible or easily ignitable vapours, liquids and dusts are on hand and everywhere where there is a potential explosion risk from sparks. This concerns not only the above fields but also petrochemicals, paint finishing shops, tank depots and fire services to name but a few. In contrast to the usual steel tools, the forging process is not the optimum manufacturing one as far as nonsparking tools are concerned. Whilst forged tools can be of the non-sparking variety, their drawback is one of suddenly breaking in instances of overloading. In contrast, cast non-sparking tools simply bend when overloaded. That is why non-sparking spanners must be of a greater material thickness, therefore their walls are thicker for the same torque value. Even so, their material is softer and thus weaker and this prevents any risk of breaking and the resulting sparks. Only those kinds of raw materials and substances/alloys such as special bronze, berylium bronze and wood - where sparks can be largely ruled out are used for manufacturing non-sparking gedore hand tools.

In the fields of application mentioned at the beginning, it must at ensured at all times that Selection is given to the lowest tool hardness which just suffices for the work on hand. After all The softer the tool , the lower the probability of sparks forming. Gedore has already dealt with this safety step for you.. We use the optimum possible material for each and every tool. As such, a letter standing for the material in question is found in the item number - for special bronze and for copper beryllium (cube). The use of non-sparking tools represents just one step in stopping explosions, avoiding fires Starting and cutting back on sparks possibly arising when hand tools are used. The talk usually is of non-sparking or anti-spark tools. What areas of use with a risk potential do you know of in your daily work Are you already using the appropriate non-sparking tools? Your gedore dealer would be pleased to advise on the right tool to be chosen.

Tags:

- Safety tools

- Non sparking tools

Other Details:

- However, it would be better to refer to low-spark, since Ignitable sparks cannot be 100% prevented even when these tools are used.

Specification

|

Minimum Order Quantity |

1 Set |

|

Material |

Aluminium Bronze |

|

Size |

all sizes |

|

Socket Sizes |

all sizes |

|

Type Of Tool |

Spanner |

|

Warranty |

6 Months |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Tools' category

"We Want Inquiries From Gujarat And Near By Locations Only"